When it comes to comfortable seating, what you see on the outside doesn’t count nearly as much as what you can’t see on the inside. It all comes down to the chair foam used to construct the seat and back. Plastic and mesh seats and backs are generally more comfortable than wooden seats and backs. But with cushioned dining chairs, it’s a bit more complicated.

So, let’s talk about the importance of high-density banquet chair foam.

Why Chair Foam Quality Matters

When you buy commercial banquet chairs that you intend to use for years, you need to prioritize chair foam quality. Chairs with low-quality, low-density chair foam become noticeably less comfortable over time. You’ll also get more consistency in the shape and design of your furniture if you choose chairs with higher-quality foam.

An Overview of Your Banquet Chair Foam Options

Not sure how to judge one chair with foam cushions against another? Here’s what you need to know when you select foam dining chairs.

Polyurethanschaum versus Polystyrolschaum

People sometimes confuse polyurethane foam with polystyrene foam.

When you think of polystyrene, think of foam cups or the styrofoam that protects assemble-it-yourself furniture inside the box. Polystyrene is stiff and rarely (if ever) used as a chair cushion—sitting on it would feel a lot like sitting on cardboard.

When you think of a chair cushion, you are likely thinking of polyurethane foam—this material is softer to sit on and molds to the shape of your body.

Polyurethane is the preferred material for banquet chair cushions because of the cushiness of the foam and several other additional advantages.

- Polyurethane foam is twice as resistant to heat and cold as polystyrene, and it continues to maintain flexibility through temperature changes. This means chairs with polyurethane foam will hold up better in storage, regardless of temperature and other conditions.

- Polyurethane does not melt, unlike polystyrene, and it’s superior when it comes to fire resistance. Polyurethane is also resistant to chemical damage, oxidation, and even sunlight. In fact, polyurethane withstands being stacked, carted around, and stored better than polystyrene.

- Polyurethane foam is much more flexible and durable than polystyrene, which makes it ideal when constructing high-quality banquet chairs.

Geschlossenzelliger Schaumstoff im Vergleich zu offenzelligem Schaumstoff

Closed-cell foam (methylene diphenyl diisocyanate or MDI) is of higher quality than open-cell foam (toluene diisocyanate or TDI). MDI foam is much more durable, which means the chair will maintain its original level of comfort for longer. It’s also more comfortable to sit on from the start. Additionally, MDI foam is more environmentally friendly and durable, and it absorbs less from spills and such.

If the aesthetic of a chair is important, you definitely want chairs with MDI foam. It’s manufactured using a mold so it can be sculpted into a variety of shapes and sizes, whereas TDI foam is precut, and it is normally seen in chairs with a generic square seat and back.

TDI-Schaum zerfällt oft. Wenn Sie jemals ein Boot oder einen Lastwagen gesehen haben, dessen Sitze gesprungen sind und der Schaum austritt, dann ist das TDI. Es ist bei weitem nicht so haltbar wie MDI-Schaum.

TDI is less expensive than MDI, so you may pay more upfront for chairs with MDI foam. However, those initial costs are offset by the longer life of the higher-quality chair.

High-density chair foam versus low-density chair foam

It can be easy to confuse weight and density, but in a chair with foam cushions, these two traits are not the same. Weight refers to how much the foam actually weighs in pounds or kilograms, whereas density is more about the quality and durability of the foam.

However, it’s generally true that higher-density chair foam is heavier, more solid, and more durable. Lower-density foam is lighter and easier to move around, but cushions made of low-density foam are also more likely to break down quickly and lose their shape. Low-density foam is also less comfortable to sit on for long periods, such as during an 8-hour conference or a long wedding reception.

What is the Recommended Foam Density Rating for a Seat Cushion?

One way to judge a cushion’s density is via its firmness rating. A firmness rating indicates the feel of the foam and how it yields to weight and pressure. Firmness is tested to illustrate how a material will bear weight. It’s measured using ILD mechanical performance testing (Indentation Load Deflection). If a foam sample requires 36 pounds of pressure to indent it 1 inch, its ILD rating is 36.

Foam density recommendations for seat cushions vary based on the type of usage for the furniture. For commercial usage, a firmer seat cushion is recommended because it will last longer and provide support during long meetings. For residential usage, a softer cushion can be appropriate, depending on the preference of the homeowner. MityLite recommends a medium to firm foam density for seat cushions in a commercial setting because this allows enough softness for comfort and enough support for long-term use.

Why Foam Density and Firmness Ratings Matter When Choosing Banquet Chairs

With all that information in mind, what you should be looking for is a banquet chair style with high-density MDI foam seat cushions. The most comfortable banquet chairs have seats and backs constructed using foam with the right balance of density and ILD rating.

If a chair with a foam seat has a low-density cushion, a person will eventually sink through the foam after sitting for a long period of time. We call this bottoming out. It’s incredibly uncomfortable because the person is basically sitting on the seat base of the chair, which is likely made of wood or plastic.

However, if the foam is too dense, it will feel uncomfortable right away and make sitting for long periods of time unpleasant. Therefore, you want a foam seat that is neither too soft nor too stiff, adjusted as necessary to the environment. Institutional use may call for much stiffer cushions than would be appropriate for home or even office use. Foam cushions with very high ILD ratings are usually on the “too stiff” side of that spectrum.

Der MityLite-Schaum

MityLite manufactures our foam in-house for most of our comfort seating line, including our most popular chair, the Klassische Serie. This enables us to save money on materials, allowing us to pass savings on to the customer.

MityLite foam is MDI polyurethane with a 65% ILD rating. Manufacturing MDI foam is much more environmentally friendly and safe because it emits fewer vapors into the air. Those who make TDI foam are required to have extra safety and pollution control measures in place and an elaborate cleanup process. This infographic shows exactly what we do to make our high-density chair foam cushions.

Step 1: Pouring the Formula into the Mold

MityLite uses a formula of isocyanate and polyol to make our special banquet chair foam. We use about twice as much polyol, which is an organic compound, as isocyanate, which is intended to make the foam stiffer, so it holds its shape.

Step 2: Removing Foam from the Mold

Each cushion is removed from the mold by hand and checked to make sure it meets our size and quality standards.

Step 3: Crushing Process

The crushing process opens up the foam cells to help ensure durability and comfort.

Step 4: Edge Trimming

If the cushion comes out of the mold with extra material on the edges, it is trimmed to fit our chair seat specifications.

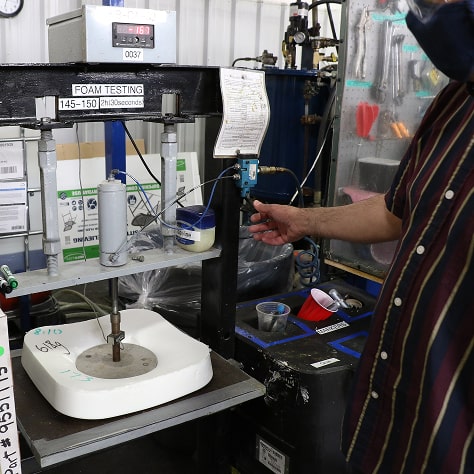

Step 5: Testing

The testing process for our foam cushions is rigorous and standardized. Two hours after the cushion is removed from the mold, the cushion is crushed and held for 30 seconds and then crushed again for an additional 30 seconds to test for durability. The cushion is tested again four days later to make sure it will hold its shape.

Shop for MityLite Banquet Chairs, oder kontaktiere uns to get a custom quote and guidance on the right chairs for your needs.

Chatten Sie noch heute mit einem engagierten Vertriebsmitarbeiter!